BioBrella benefits at a glance

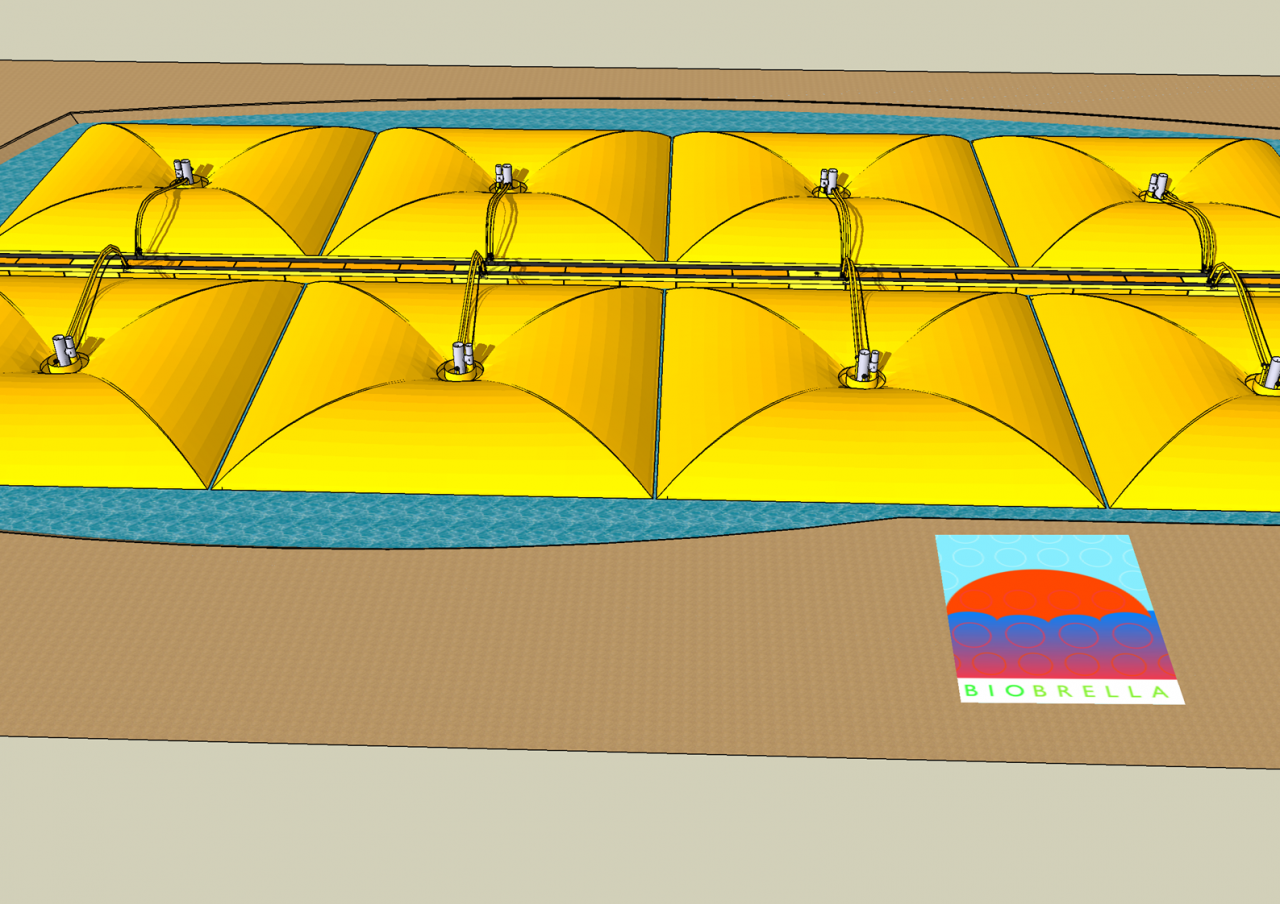

- Modular concept; applicable to most sites with existing anaerobic lagoons

- Huge reduction of engineering time/cost by (re-)use of existing lagoons

- Scalable by the number of identical units installed. The entire BioBrella Facility can be expanded as needed

- Entire plant shipped as prefabricated containerized package units, which are thoroughly tested before shipment to the site.

- Quick installation (huge time reduction in comparison with existing lagoon and in-tank technologies)

- Very fast commissioning. No or little biological seeding requirement. Minimal disruption to on-going operations

- Modular system increases the flexibility and reliability of the total BioBrella system by an order of magnitude

- Very low parasitic load

- Individual BioBrella units are extremely strong and safe. No electrical connections exist between ex-rated areas and the central control system

- BioBrella units do not need to cover the entire area of the lagoon as biogas production is specifically directed under the dome cover area

- BioBrella plants operate automatically but can be accessed by remote control and data monitoring. Extensive diagnostic and operation reports can be sent to operators periodically or on request.

- Suitable for tapioca waste, Palm Oil Mill effluent, selected ethanol production plants, food, dairy, meat processing waste and many other waste streams

- Optional other applications: disaster relief sanitation, small communities and factories